While transactional efficiency lies at the core of any business, engineering is at the heart of the operations. Using our experience, we bring together many aspects of Engineering to contribute to increasing the operational efficiency of each process and product. Using complex algorithms, we build a virtuous cycle. Where we analyse the:

The foundation of any manufacturing organization rests on an agile Product Mix. Engineering BOMs/ Manufacturing BOMs and Service BOMs should be in sync. Drive enquiry into:

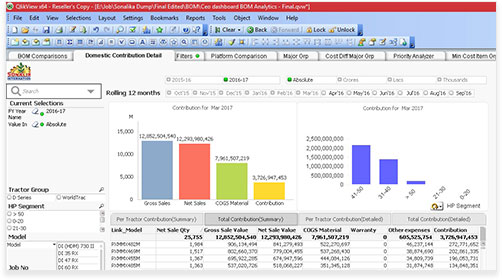

“Contribution” is the Price of the Model minus the cost of materials. Defining the model mix of the organization basis:

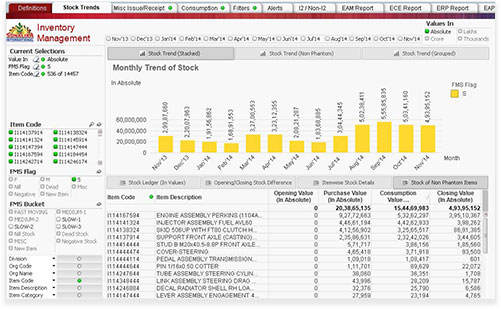

Optimize inventory costs, both direct and indirect by identifying:

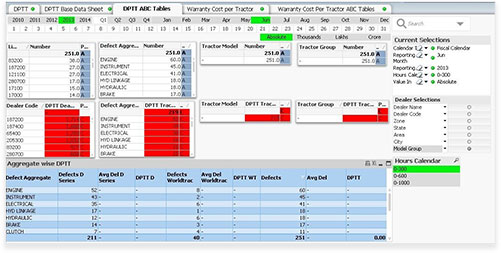

Use Service and Warranty analytics to identify:

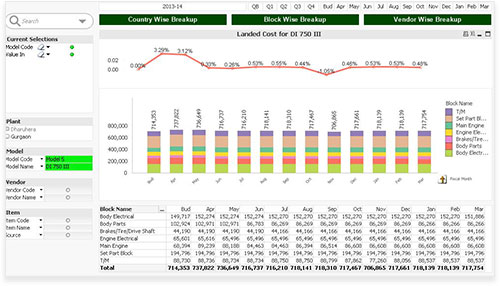

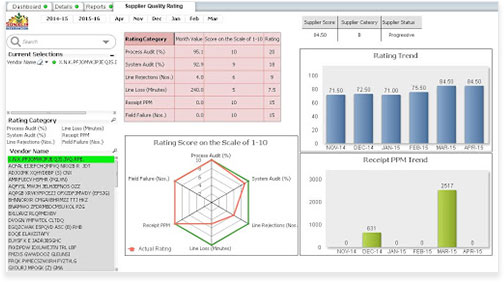

Vendor ratings based on cost and quality help to bind the product stack completely. Analyze the vendors as a whole and as individuals - across aggregates and commodity.