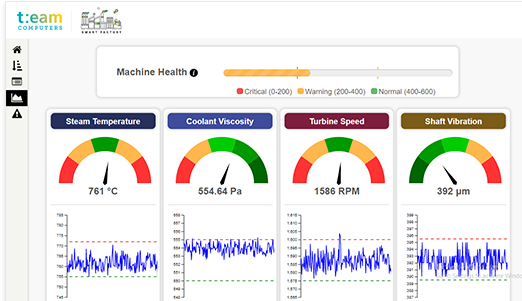

Predictive maintenance can help companies and individual consumers avoid vehicle downtime and can offer other insights regarding automotive part wear and usage patterns. Long term, it also has the potential to offer cost savings—not simply because vehicles can stay in operation reliably, but also because it can reduce repairs and improve safety outcomes. If vehicle maintenance is performed before equipment loses performance, unplanned service downtime may be a thing of the past.

Vehicle breakdowns are annoying and expensive. In many cases, vehicle failures can be avoided through preventive, vehicle-specific maintenance. But when is the right time? The innovative Predictive Diagnostics software solution monitors, evaluates and reports component and system conditions in the vehicle. Based on data from the connected vehicle as well as cloud information, faults can be predicted and fixed in time – in an individual, state-based and precise manner.

Optimized maintenance management with Predictive Diagnostics reduces overall vehicle operating costs and increases vehicle availability. This benefits OEMs, fleet operators and private users! Whether you're off on a family vacation, carrying goods by truck or working on a large off-highway construction site, Predictive Diagnostics can help prevent unexpected breakdowns by reliably predicting system and component failures. With Predictive Diagnostics, car drivers or vehicle dispatchers know the current and future condition of their vehicles, as well as any work scheduled. This makes it possible to determine the latest point at which maintenance is pending, so that a pending vehicle failure can be combined with an already planned maintenance visit.